Running notes to track fixes and improvements to the Thrustmaster T300RS. Lets see how far this goes before I have to upgrade to a direct drive wheel 🤞.

Broken Hall Sensor Bracket

This seems to be a common problem, with the main symptom being that the wheel loses center in-game.

Trying to recalibrate it doesn’t fix the issue, as it will lose center again later on.

NOTE

Manual calibration can be performed by following the steps outlined here

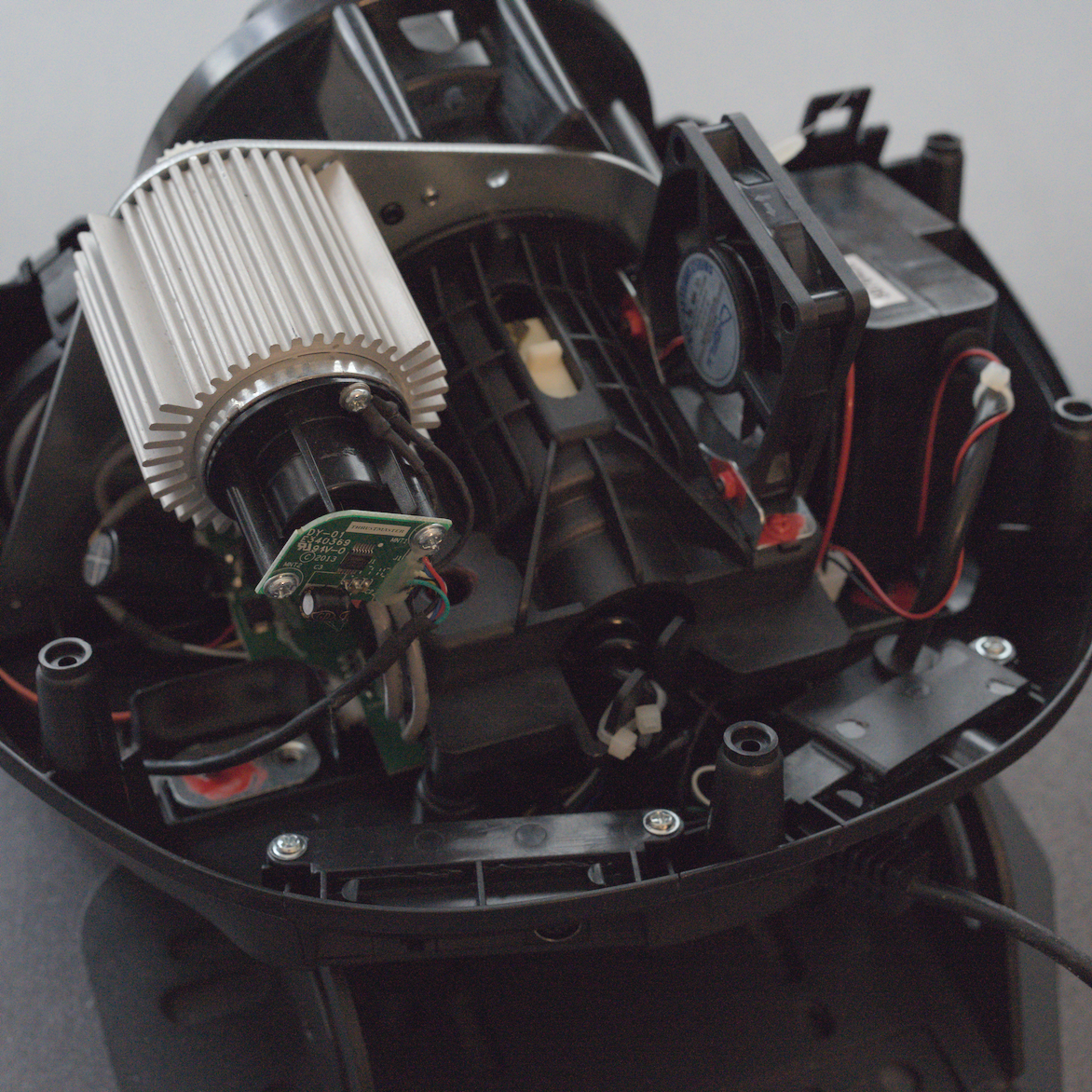

Time to open up the T300 to see if that’s the issue!

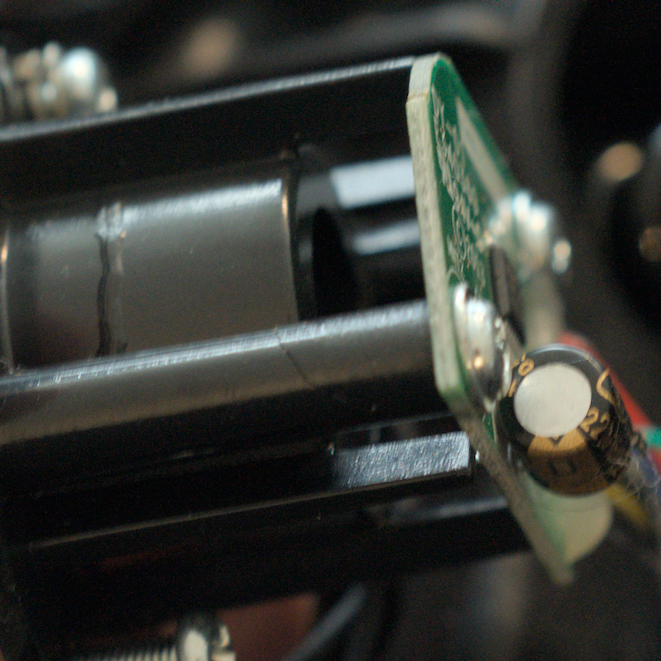

Pulling out the bracket and applying a bit of pressure at the mounting point reveals the issue.

Luckily, there are many existing 3D models of the bracket. I ended up printing this version.

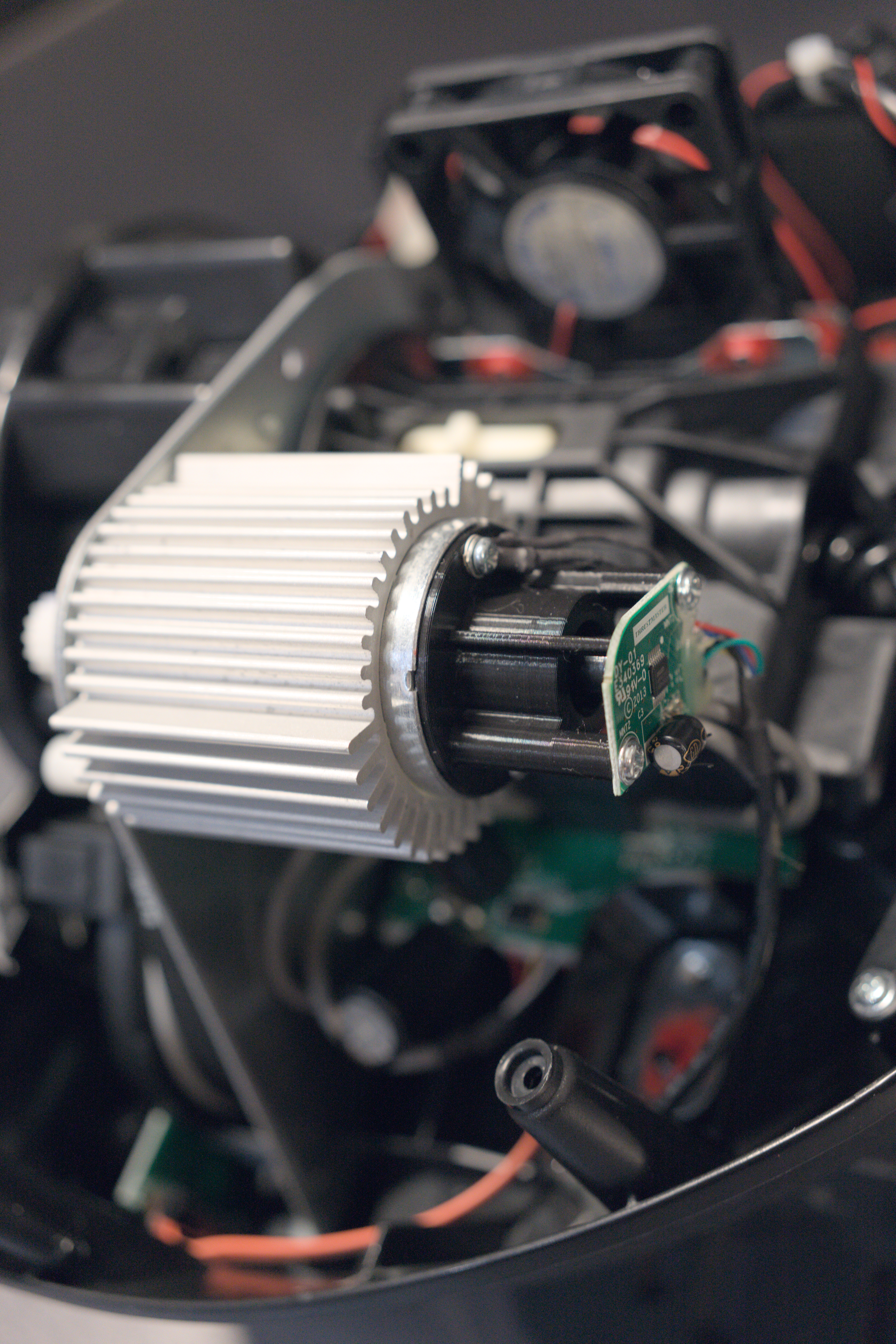

Here is the 3D printed bracket re-attached to the motor. It’s recommended to print the part using either PETG or HT-PLA.

Before putting everything back together, run the motor calibration software, then do a few laps to make sure the wheel stays centered.

Cooling

Another common issue is cooling, where the force feedback gets throttled during long sim sessions.

Modifying the Airflow

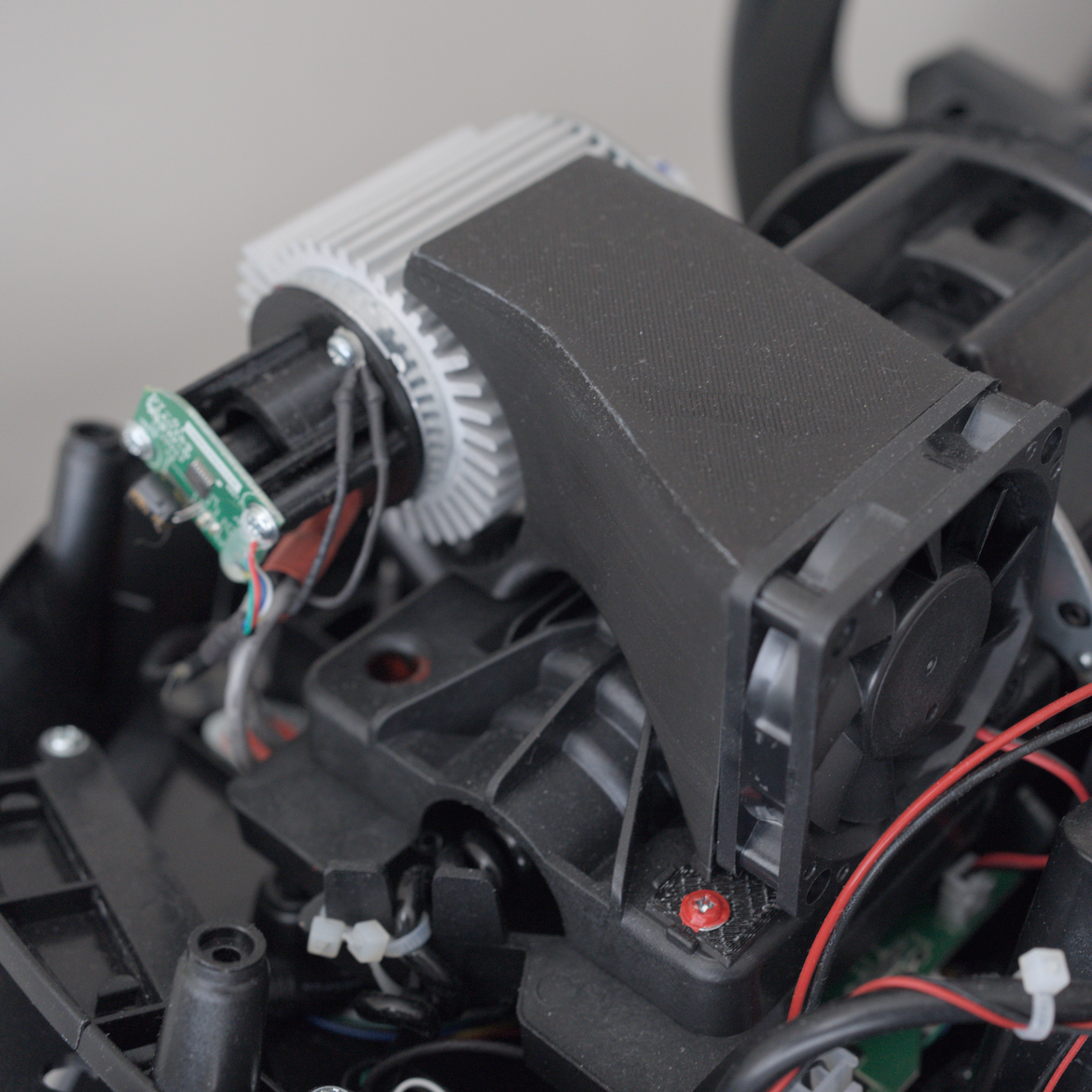

Since I printed the hall sensor bracket using PLA, I was concerned about its durability during long races.

While browsing forums and Reddit, I found someone had created a funnel to direct airflow directly at the motor.

Final setup (seems to be working for now):

Later on, I might try drilling some holes as shown here to further improve circulating airflow.